Introduction: since zeroing is set when the machine tool is assembled or programmed, the zero coordinate point is the initial position of each component of the lathe. The restart of the CNC lathe after the work is powered off requires the operator to complete the zeroing operation, which is also a knowledge point that every CNC processing practitioner needs to understand. This article will mainly introduce the meaning of zeroing CNC lathe.

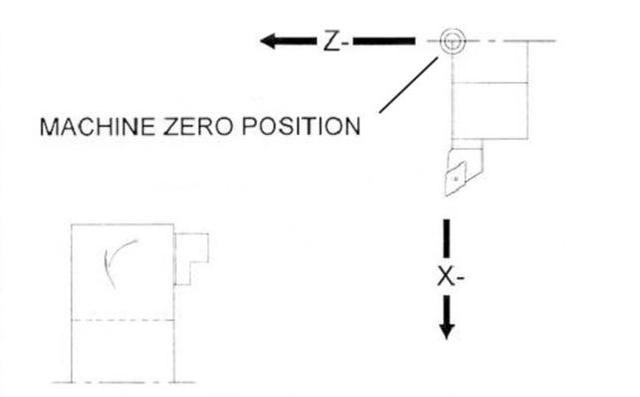

Before the CNC lathe starts to process parts, its operators need to set the zero point of the lathe, so that the CNC lathe knows where to start. The starting position is the zeroing program used in programming. All initial lathe offsets are based on zero coordinates. This offset is called geometric offset, which establishes the distance and direction between the zero coordinate and the tool reference point. This reference point is just a fixed point of the tool itself.

After the CNC lathe is correctly zeroed and the soft limit is set, the CNC Lathe will not touch the physical limit switch. If at any time a command is issued to move the CNC lathe beyond the soft limits (when they are enabled), an error will appear in the status line and the movement will stop.

What is zeroing of CNC lathe

Modern CNC lathes generally use incremental rotary encoder or incremental grating ruler as position detection feedback components. They will lose the memory of each coordinate position after the CNC lathe is powered off, so each time you start the machine, you must first return each coordinate axis to a fixed point of the lathe and re-establish the lathe coordinate system.

NC lathe zeroing is actually the benchmark corresponding to 0 and 0 coordinates on CAD drawings, which is used to create G code and complete other cam work. In G code program, x0, Y0 and Z0 represent the zeroing position of NC lathe. The G code instruction is an instruction that tells the CNC lathe what to do in the process of machining and cutting, including guiding the spindle to move a specific distance on each axis. All these movements require a known starting position, that is, the zero coordinate. It can be anywhere in the workspace, but x/y is usually set as one of the four corners of the workpiece, or the center of the workpiece, and the starting position of Z is usually set as the top material of the workpiece or the bottom of the working material. CAD software will generate G code according to the given zero coordinates.

These points are not directly referenced in the part program. As a CNC lathe operator, you must know where the zero coordinate is and where the tool reference point is. The setup table or tool table can be used for this purpose, and the standard company policy may be another resource. It is also helpful to explain the programmed dimensions. For example, if the dimension from the front to the nearest shoulder is specified as 20mm in the drawing, the operator can see 2-20.0 in the program to obtain information about key settings.

What should be paid attention to when the CNC lathe is zeroed

The zeroing process of CNC lathe starts from Z axis, then x axis, and finally Y axis. Each axis will run towards its limit switch until it engages the switch, and then will run in the opposite direction until the switch disengages. Once all three axes have reached the limit switch, the CNC lathe equipment can run over the entire length of each axis.

This is called the reference motion of CNC lathe. Without this reference motion, the CNC Lathe will not know its position on its axis and may not be able to move back and forth over the entire length. If the CNC lathe stops within the whole travel range and there is no jamming, please make sure that all zeroing is completed and try to run again.

An important thing to note is that if any axis runs in the opposite direction of its limit switch when returning to zero, please check to ensure that the limit switch is not engaged in a position on the NC lathe. All limit switches are on the same circuit, so if you need to let the CNC lathe and the y-axis limit switch is pressed, the z-axis will move in the opposite direction. This happens because the CNC lathe equipment is going through the zeroing phase, when it returns from the switch until it disengages. Because the y-axis switch is pressed, the z-axis will try to move away indefinitely, but it will never disengage.

This article mainly introduces the meaning of NC lathe zeroing. Browsing the full text, you can understand that NC lathe zeroing is actually the benchmark corresponding to 0 and 0 coordinates on CAD drawings, which is used to create G code and complete other cam work. In G code program, x0, Y0, Z0 represent the position of NC lathe zeroing.

Post time: Jul-19-2022