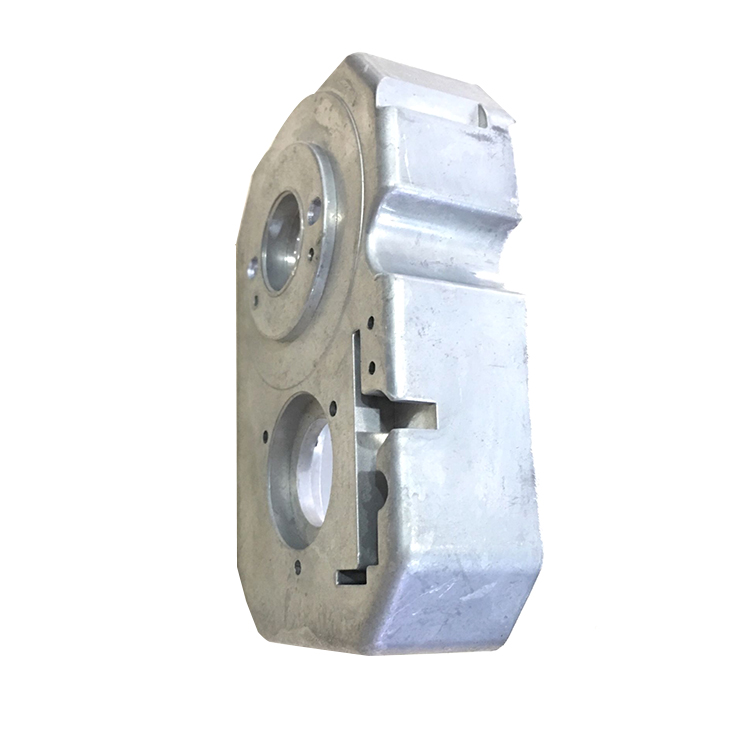

China wholesale Cnc Surface Grinder Supplier – We can make Aluminum Alloy/Magnesium Alloy/Zinc Alloy Parts By Die Casting or Pressure Casting – Leirui Mould Detail:

Specifications

| Material | Aluminum alloy: ADC12, ADC10, A360, A380, A356

Magnesium alloy: AZ91D, AM60B Zinc alloy: ZA3#, ZA5#, ZA8# |

| Processing Technology | Design→Molding→Die-Casting→Drilling→Drilling→Tapping→CNC Machining→Polishing→Surface Treatment→Assembly→Quality Inspection→Packaging→Shipping |

| Tolerance | ±0.02mm |

| Surface Treatment | Powder spraying, oil spraying, sandblasting, polishing, grinding, passivation, chrome plating, zinc plating, nickel plating, electrophoresis, anodizing, etc. |

| Quality System&Testing | ISO9001:2015, SGS test report |

| Main Testing Equipment | Dimensional detector, Automatic image measuring instrument, Salt spray tester, Air tightness detector, Dynamic balance detector |

| Features and Benefits | 1. High machining accuracy, flatness within 0.1mm.

2. High strength, not easy to deform, with good electrical and thermal 3. The surface finish is high, and the surface roughness after processing is Ra1.6. 4. High machining accuracy and seamless assembly structure. 5. No particles, no pitting, no paint peeling on the appearance. 6. The appearance is smooth and the 7. Passed 20,000 wear resistance tests. 8. Pass the 96-hour salt spray test. 9. Pass the coating adhesion test and scratch resistance test. 10. Pass the 100 grid test and 3M glue test. 11. Pass the film thickness test. |

Our Advantages

1) Design assistance and full engineering support .

2) Professional at OEM & ODM parts .

3) Excellent after sales service.

4) Advanced machine tools, CAD/CAM programming software.

5) Prototype machining capabilities.

6) Strict quality control standards with a highly qualified inspection department .

7) Continually upgrading and advancing our equipment to remain competitive .

8) Small quality is also available.

FAQ

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client’s needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers’ requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, paypal, western union, moneygram etc.

Q: Is it possible to know how is myproduct going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining progress.

Product detail pictures:

Related Product Guide:

In the past few years, our company absorbed and digested advanced technologies both at home and abroad. Meanwhile, our company staffs a team of experts devoted to the development of China wholesale Cnc Surface Grinder Supplier – We can make Aluminum Alloy/Magnesium Alloy/Zinc Alloy Parts By Die Casting or Pressure Casting – Leirui Mould, The product will supply to all over the world, such as: Maldives, Ecuador, USA, We will not only continuously introduce technical guidance of experts from both home and abroad, but also develop the new and advanced products constantly to satisfactorily meet the needs of our clients all over the world.

This company can be well to meet our needs on product quantity and delivery time, so we always choose them when we have procurement requirements.

-

China wholesale Cnc Sheet Metal Fabrication Sup...

-

China wholesale Choong Fei Die Casting Factory ...

-

China wholesale Shield Aluminium Die Castings F...

-

China wholesale Cnc Plywood Cutting Supplier &#...

-

China wholesale Samundi Die Casting Supplier &#...

-

China wholesale Cnc Routing Plastic Manufacture...