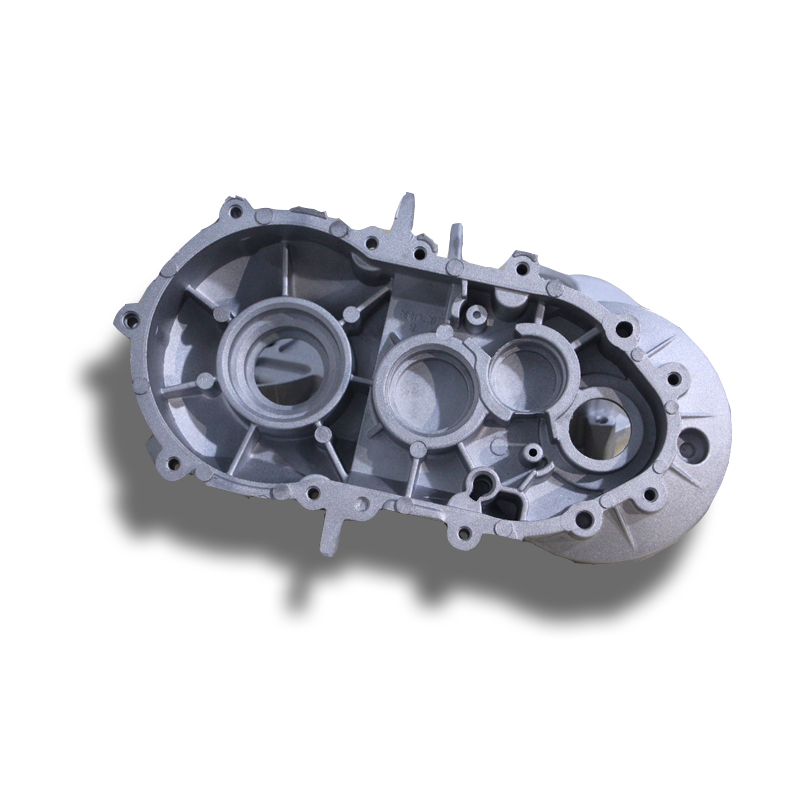

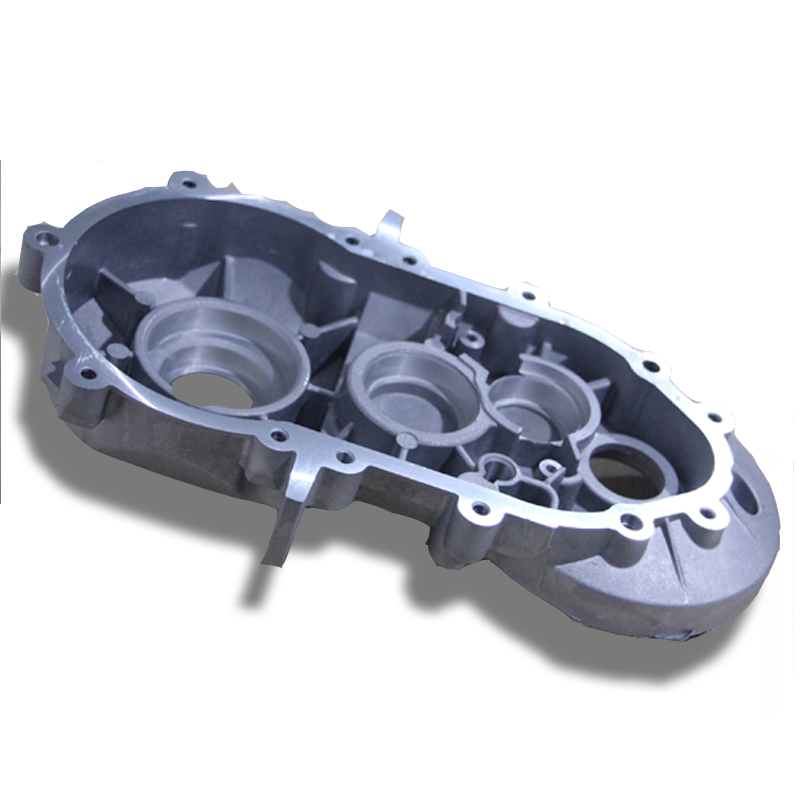

China wholesale A380 Die Cast Aluminum Factory – Automobile Spare Parts Gearbox Shell Custom Die Casting CNC Machining Aluminum Parts – Leirui Mould Detail:

Specification

| item | Gearbox |

| CNC Machining or Not | Cnc Machining |

| Type | Milling |

| Material Capabilities | Aluminum, Hardened Metals |

| Micro Machining or Not | Micro Machining |

| Place of Origin | China |

| Chongqing | |

| Model Number | customized |

| Brand Name | henghui |

| Product name | Gearbox |

| Materials Avaliable | Aluminum Stainless Plastic Metals Copper |

| Process | Cnc Machining |

| Surface treatment | Customer’s Request |

| Application | Auto |

| Color | Sliver |

| Service | Customized OEM |

| Drawing Format | 2D/(PDF/CAD)3D(IGES/STEP) |

| MOQ | 100pcs |

| Delivery Time | 15-25 Days |

CNC Machining

1. Vertical machining center: A machining center whose spindle is in a vertical state in space is called a vertical machining center. The vertical machining center machine should be suitable for processing complex parts such as plates, discs, molds and small shells. The vertical machining center can complete the processes of milling, boring, drilling, tapping and thread cutting.

Vertical machining centers are rarely three-axis and two-linkage, and generally can achieve three-axis and three-linkage. Some can carry out five-axis, six-axis control. Compared with the corresponding horizontal machining center, the structure is simple, the floor space is small, and it is more affordable.

2. Horizontal machining center: A machining center whose spindle is horizontal in space is called a horizontal machining center. Horizontal machining centers are suitable for mass production of products with complex shapes and high precision requirements, especially the processing of boxes and complex structural parts. It is used extensively in the automotive, aerospace, marine and power generation industries for the precise and efficient machining of complex parts. Compared with the vertical machining center, the horizontal machining center has a complex structure, a large area, and a high cost. Moreover, the horizontal machining center is inconvenient to observe during machining, and it is inconvenient to clamp and measure parts, but it is not convenient for chip removal during machining. Easy, good for processing.

3. Compound machining center: The spindle of the machining center can be converted horizontally and vertically, which is called a vertical and horizontal machining center, and also becomes a compound machining center. The compound machining center completes a variety of machining procedures by clamping the workpiece at one time, which shortens the machining time and improves the machining accuracy. CNC turning and milling compound machining center is the main model of compound machining center. It usually realizes machining processes such as plane milling, drilling, tapping, and slot milling on CNC lathes. It has compound functions such as turning, milling, and boring. to complete the entire process.

Product detail pictures:

Related Product Guide:

Persisting in "High high quality, Prompt Delivery, Aggressive Price", we've established long-term cooperation with clients from the two overseas and domestically and get new and old clients' superior comments for China wholesale A380 Die Cast Aluminum Factory – Automobile Spare Parts Gearbox Shell Custom Die Casting CNC Machining Aluminum Parts – Leirui Mould, The product will supply to all over the world, such as: Lisbon, Algeria, European, By integrating manufacturing with foreign trade sectors, we can present total customer solutions by guaranteeing the delivery of right merchandise to the right place at the right time, which is supported by our abundant experiences, powerful production capability, consistent quality, diversified products and the control of the industry trend as well as our maturity before and after sales services. We'd like to share our ideas with you and welcome your comments and questions.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!