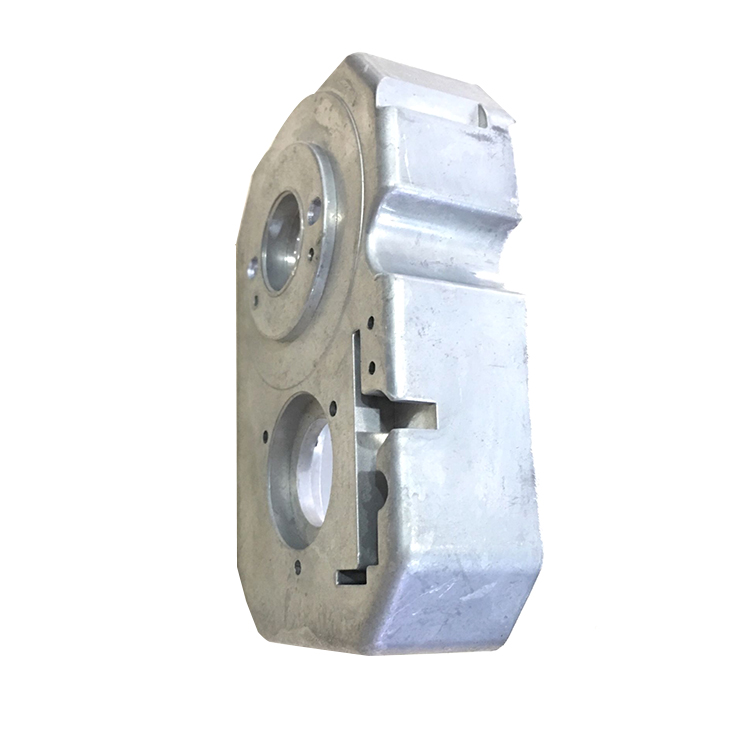

China wholesale 3d Printed Metal Lathe Manufacturer – Cast Aluminum Gearboxes Auto Gearbox Metal Foundry Still Forklift Casting For Spare Parts – Leirui Mould Detail:

What can we do

Mold Design:

For sand casting, the mold is made of wood or other metal materials. In this process, we asked our engineers to make the mold size slightly larger than the finished product, and the difference is called the shrinkage allowance. The purpose of this is to melt the metal into the mold to ensure that the molten metal solidifies and shrinks, thereby preventing voids in the casting process.

Core Making:

The core is formed by casting resin sand into a mold to form a casting of the inner surface. Therefore, the gap between the core and the mold eventually becomes a casting.

Casting Producing:

A mold is required during the smelting process. Molding typically involves the support frame of the mold, which is pulled out to separate during the casting process, where the previously placed core melts in the mold and then closes the die opening.

Cleaning & Machining:

The purpose of cleaning is to remove sand, sand and excess metal in the casting. Welding, sand removal can improve the appearance of the casting surface by burning the sand and the scale is removed to improve the appearance of the surface of the casting. Excess metal and other risers are removed. A step further by welding and grinding. Some castings are subject to special post-processing requirements such as heat treatment, shaping, anti-rust treatment, roughing, etc.

Finally, Checking the defects and comprehensive quality finishing, before processing, and then re-processing, according to the requirements of different customers, we can do heat treatment, surface treatment, additional inspection and so on.

Packing & Delivery

1. For smaller products, we will wrap the foam cotton and put it in the carton.

2. For larger products, we will stack layers, while each product is covered with foam cotton and then packed with a bubble film as a whole.

FAQ

Q: Are you trading company or manufacturer ?

A: We are manufacturer and provide both moulding and casting production for our global clients. From aluminum casting, sand casting and gravity casting to injection moulds, dia casting moulds for other manufacturers and industrial clients, we has been manufacturing both consumer product accessories and industrial hardwares for our global clients using aluminum alloy casting.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 20-30 days if the goods are custom made, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: We can’t provide free samples and will charge sample fee according to the actual product value.

Q: What is your terms of payment ?

The payment methods we accept are Paypal (less than $1000) and International Wire Transfer.

Payment Terms: T/T; Payment Terms: Mold Payment Terms: 100% up on confirmation; Part Payment Terms: 30% – 70%; Full payment before shipment for small orders; For large transactions, 30% Deposit before mass production, and 70% before shipment)

Product detail pictures:

Related Product Guide:

We support our purchasers with ideal premium quality products and substantial level company. Becoming the specialist manufacturer in this sector, we've acquired rich practical working experience in producing and managing for China wholesale 3d Printed Metal Lathe Manufacturer – Cast Aluminum Gearboxes Auto Gearbox Metal Foundry Still Forklift Casting For Spare Parts – Leirui Mould, The product will supply to all over the world, such as: Kenya, Libya, Montreal, Our company will adhere to "Quality first, , perfection forever, people-oriented , technology innovation"business philosophy. Hard work to keep making progress, innovation in the industry, make every effort to first-class enterprise. We try our best to build the scientific management model, to learn abundant professional knowledge, to develop advanced production equipment and production process , to create the first-call quality products, reasonable price , high quality of service , quick delivery , to give you create new value .

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!

-

China wholesale A380 Die Cast Aluminum Manufact...

-

China wholesale A380 Aluminum Heat Treatment Su...

-

China wholesale Cnc Plastic Machining Suppliers...

-

China wholesale Vacuum Die Casting Manufacturer...

-

China wholesale Maverick Cnc Manufacturers R...

-

China wholesale Star Swiss Lathe Manufacturers ...